Our longtime readers will understand why we’re so excited about Libro.fm’s sale of audio books for under $5 each, in honor of Independent Bookstore Day on April 30.

After all, in our (gulp) 15+ years online, we’ve shared hundreds of the best books and audio books, along with a commitment to supporting local and indie bookstores when that’s an option for you.

So here’s the deal:

This limited-time offer from Libro.fm begins today and runs through April 30. 2023. Over one thousand (yes, one THOUSAND) audio titles will be on sale for $5 or less. And what makes this so special for your own community is that you choose which of Libro.fm’s 2000+ independent bookstore partners you want to support with your purchase.

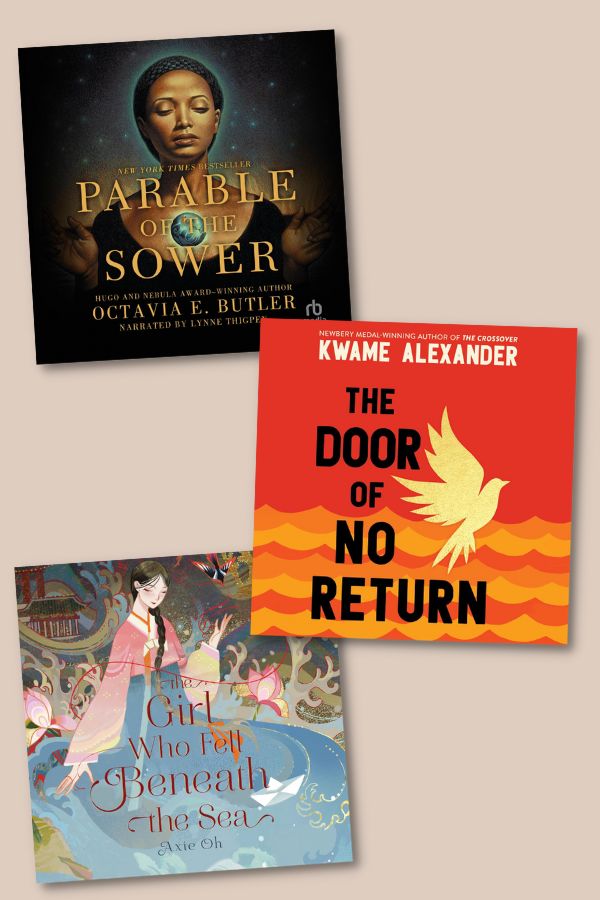

We love that you can direct your dollars locally without leaving your home and get some truly great books. I have my eye on Parable of the Sower by Octavia E. Butler, The Door of No Return by Kwame Alexander, and The Girl who Fell Beneath the Sea by Axie Oh.

This post contains affiliate links and purchases may generate a small commission to help support our work at no additional expense to you.Thank you for supporting independent publishers. And bookstores!

Related: Not into audiobooks? Here’s the one thing that finally changed my mind.

This is such a convenient and affordable way to stock up on summer reading and audio books for your next road trip or your daily commute. Or, just download a few juicy novels to listen to while you watch the kids play outside. Audio books are such an easy way to bring great storytelling into your life without losing focus on what’s going on around you — an important benefit for us parents who need to pay attention to so many things at once.

Bonus: if you’d prefer to browse the shelves before you buy? Libro.fm will hide a “Golden Ticket” at 250 of their bookstore partners on April 29th that can be redeemed for twelve free Libro.fm audiobooks.