by Liz Gumbinner | Internet Safety, Tips and Tricks

This week’s Washington Post article about the teenage boy sextortion scam by Chris Moody is all I’ve been thinking about. In part because I know a kid who was targeted in this way, and it was a terrible situation. But to learn that this is a problem...

by Christina Refford | Games + Gaming, Internet Safety

We know many so many families who love online gaming for its temporary escape into cool unique realms and the connection with others who love to play as much as we do. But sometimes real-world problems can follow us into our online games; bullying, harassment, or...

by Liz Gumbinner | Internet Safety, Social Media, Tips and Tricks

Thinking about leaving Twitter? (Are we calling it Twexit yet?) With the big changeover in management this week, some Twitter users are leaving, some users are staying, and your choice is up to you. Either way, it’s good idea to download your Twitter data...

by Christina Refford | Best Apps, Internet Safety, Social Media

You may have seen this hilarious sketch on SNL that has a bunch of adults using the app BeReal during a rather tense situation. (if you haven’t seen it yet, go watch now! I’ll wait.) This sketch does a great job explaining what BeReal is, but we’ve...

by Christina Refford | Games + Gaming, Internet Safety, Social Media, Tips and Tricks

Recently, Meta announced it would be launching new parental safety controls for teens in the form of tools and resources for both the Instagram social media app and their Meta Quest VR gaming headsets. The goal is to help parents better manage what our teens are...

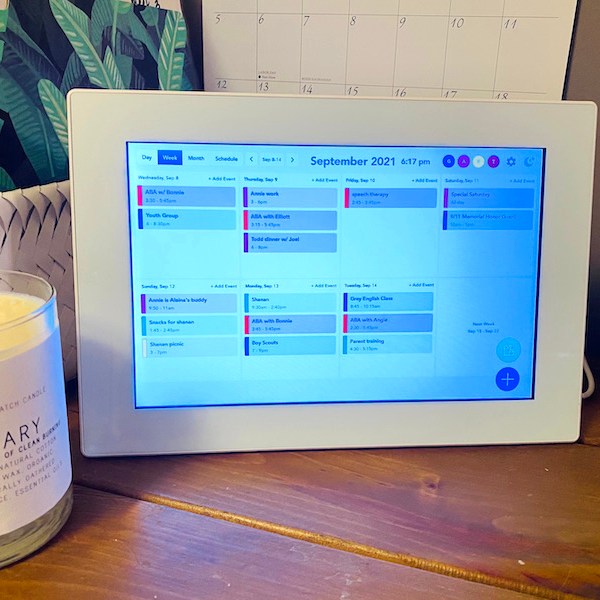

by Liz Gumbinner | Gear + Hardware, Internet Safety, Kids, Tips and Tricks

We’ve officially hit the point of full Apple product saturation in our household — and as so many parents in our Out Tech Your Kids community tell us, they have too. So what do you do when you’re all basically on Apple devices, your kid needs a new...

by Liz Gumbinner | Internet Safety, Tips and Tricks

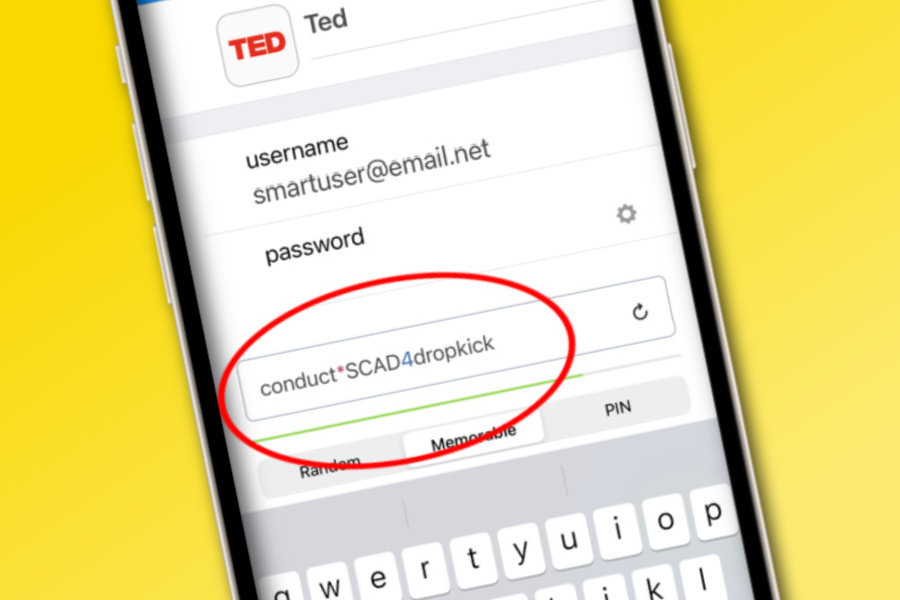

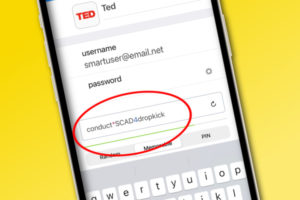

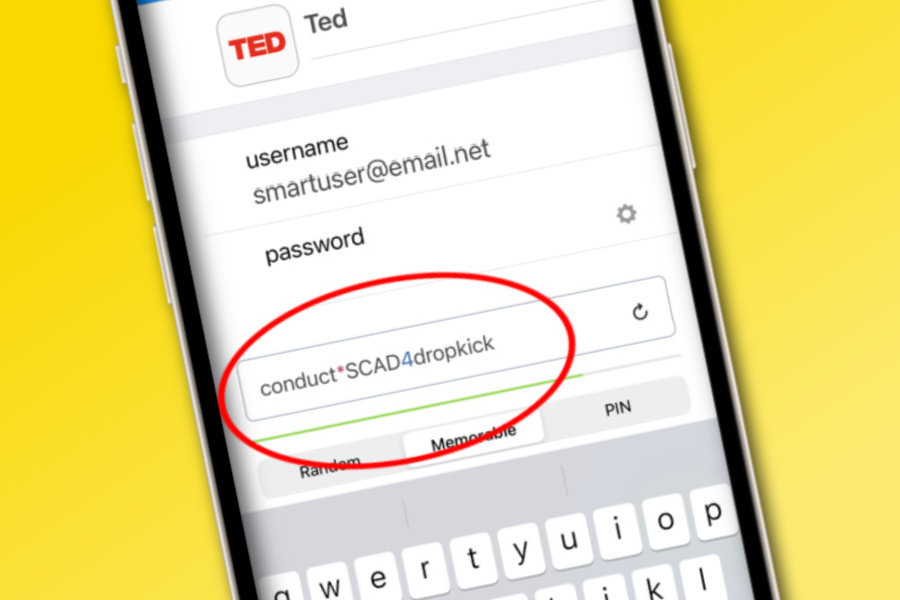

With the new year here, it’s a good time for a refresher on how to make strong passwords and help keep them safe. With phishing on the rise, ever-present social media hacks, and general security breaches and unsavory shenanigans, it’s just a good idea, and...

by Liz Gumbinner | Internet Safety, Kids, Social Media

We’re all talking about “that” Wall Street Journal article about Instagram: Facebook Knows It’s Toxic for Teen Girls. You’re probably talking about it. Or your kids are. I know it’s all we’ve been seeing in our social feeds...

by Liz Gumbinner | Best Apps, Internet Safety, Tips and Tricks

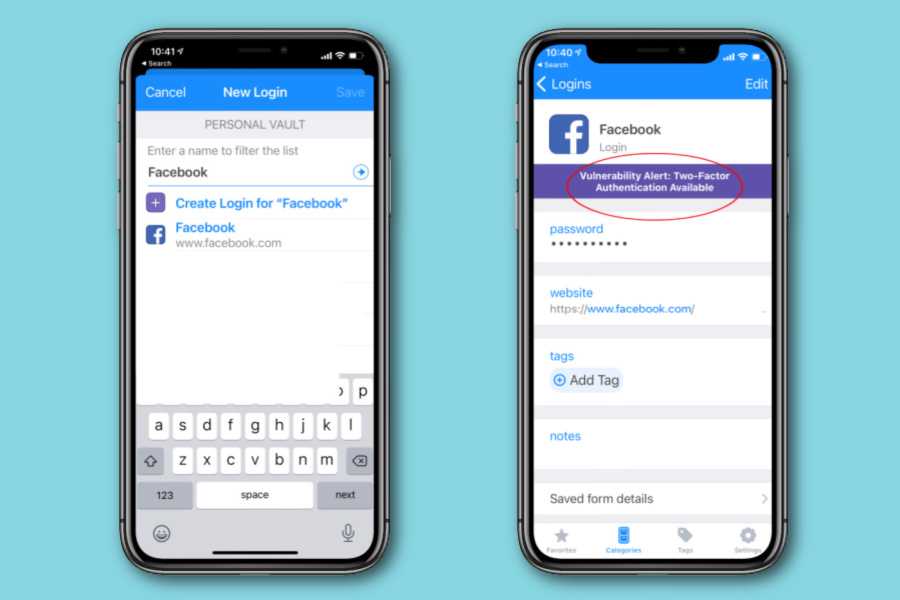

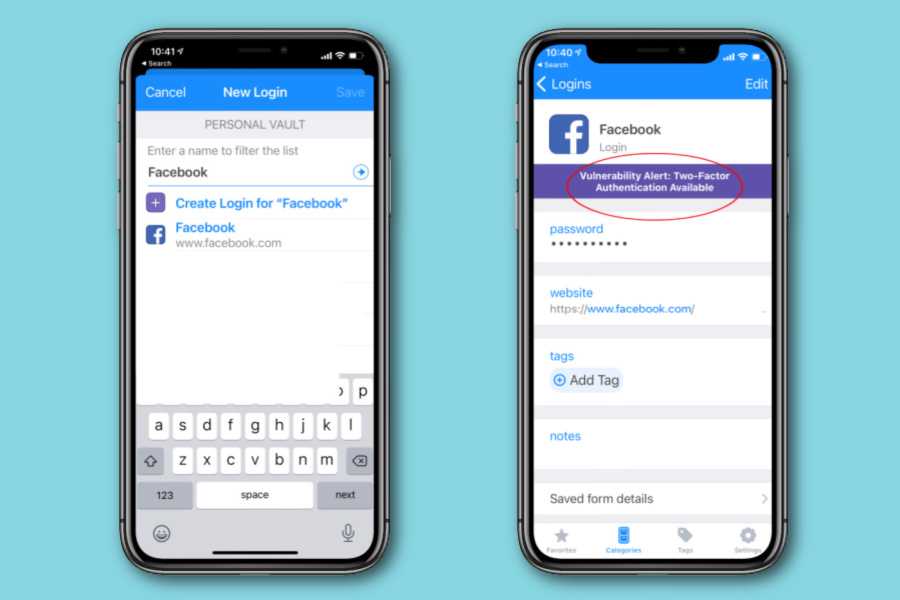

This week in our Out Tech Your Kids Facebook group, we were asked how to prevent a Facebook hack, and specifically, if were any security measures to take that might help. And yes, yes there are! Here, a few really simple tips to help prevent a Facebook hack. They can...

by Liz Gumbinner | Internet Safety, Tips and Tricks

Have you noticed lately there’s been a huge uptick in text spam? So of course, I want to report it to…someone. Anyone! Turns out it’s so much easier than I had expected. Now when I say text spam, I don’t mean political candidates you’ve...

by Liz Gumbinner | Best Apps, Internet Safety, Kids

With the news last week that Zoom had some big security concerns to patch up, educators of all kinds started seeking out Zoom alternatives for schools and other kinds of remote learning. Especially after the NYC DOE took the big step of forbidding NYC public schools...

by Liz Gumbinner | Best Apps, Internet Safety

If you’ve got a kid on an iPhone or an iPad, this week’s iOS 13.3 update (as well as iPad OS 13.3)has some serious parental controls that we think you’ll be happy to know about. Introducing Communication Limits Starting his week, there’s a new...